What is called a Measurement?

Measurement of a physical quantity is the process of comparing the quantity with a standard value of the quantity of same kind. The standard value is called its unit.

To express the measurement of a physical quantity, we need to know two things –

- The unit in which the quantity is measured.

- The numerical value or the magnitude of the quantity i.e. the number of times that unit is contained in the measured physical quantity.

Therefore, measure of a physical quantity ( Q ) = Numerical value of the physical quantity ( n ) \times size of the unit ( u ) .

Or, \quad Q = n u

The smaller the size of the unit ( u ) , the larger is the numerical value ( n ) associated with the physical quantity.

Types of Measurement

There are two methods for performing dimensional measurements.

- Direct measurement.

- Indirect measurement.

Direct Measurement

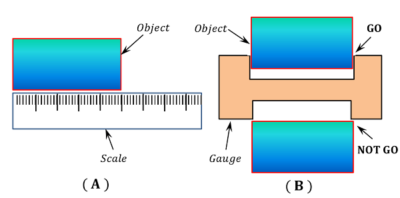

In measuring the length etc., graduated measuring instruments such as Meter scales, Vernier calipers, Micrometers, Screw gauge etc. are used to measure the dimensions of the objects by applying the instrument directly on the object. This is called direct measuring activity.

This method is also called absolute measurement.

Indirect Measurement

In this method, measuring instruments are not applied directly on the target object. The dimensions of the target object are compared using instruments such as dial gauges, feeler gauges, block gauges etc.

Indirect measurement may also use geometrical or trigonometrical relations to get the result. This method is also known as comparative measurement. It is generally employed for following reasons.

- Indirect measurement is employed at the places where it is not customary to apply the direct measuring instrument.

- It is used for the instances where it is not possible to apply the direct measuring instrument due to space constraint.

- For some applications, some allowances are allowed for the dimensions of components. The size of the component should lie in between two limits called upper limit or maximum permissible dimension and lower limit or minimum permissible dimension. For such components measurement of exact dimension is not necessary. In mass production of such components “GO & NOT GO” gauges are employed to compare the dimensions of target component.

- This may also use geometrical / trigonometrical relations or wave reflection method using LASER or RADAR to get the result of measure. Indirect measurement of height of a mountain peak, depth of sea, diameter of planets etc. are some examples.

Following figure represents the direct and indirect methods of measurement.

Precise Measurement

Precise measurement means accuracy of measuring activity.

Science gives an accurate knowledge about the nature and the natural phenomena. It expresses various natural phenomena in terms of the relationships among the quantities involved. The exactness or accuracy of these relationships depends upon the measuring technique and involved quantities.

Accuracy

Measuring accuracy refers to the closeness of a measuring results to the true value of the measuring quantity. It indicates the relative freedom from errors. As we reduce the errors, the measurement becomes more accurate.

Precision

Precision refers to the resolution or the limit to which the quantity is measured. It is determined by the least count of the measuring instrument. The smaller the least count, the greater will be the precision.

Difference between accuracy & precision

We can illustrate the difference between accuracy and precision with the help of an example.

Suppose three students are asked to find the mass of a piece of metal whose mass is known to be 0.520 \ g . They obtain the data as given in following table.

| Student | Reading 1 | Reading 2 | Reading 3 | Average mass. |

| A | 0.52 g | 0.51 g | 0.50 g | 0.51 g |

| B | 0.516 g | 0.515 g | 0.514 g | 0.515 g |

| C | 0.521 g | 0.520 g | 0.520 g | 0.520 g |

- The data obtained by the student A are neither very precise nor accurate. The individual readings are differing widely. The average value ( 0.51 g ) is far from the true value.

- The data for student B are more precise because they are varying slightly from one another but the average value is not accurate.

- The data for student C are both precise and accurate. The resolution for A is ( 0.01 g ) and that for B or C is ( 0.001 g ).

A precise measurement may achieved by –

- During measurement we require to adopt accurate measuring methods to obtain true relationship among physical quantities.

- We need to employ accurate measuring instruments called precision instruments with zero error.

- Accuracy of measurement also depends upon the accuracy of the applied techniques.

- Skill of the person making the measurement and taking readings.

- By eliminating errors such as instrumental error, imperfections and personal error etc.

The recent progress in science and technology has been possible only due to the development of high precision instruments.

Science has made possible to measure mass as small as that of an electron about ( 10^{30} \ kg ) and as large as that of the universe about ( 10^{55} \ kg )

Instruments & Gauges

Instruments and gauges both are tools used for measurement of dimensions of objects. But they have some basic differences between them.

| Sl. No. | Instrument. | Gauge. |

| 1 | A measuring instrument is a tool for direct measurement of dimensions. | A gauge is a tool for comparing dimensions of object within specified limits. |

| 2 | A instrument gives exact dimension of object. | A gauge doesn’t gives the exact dimension of object. |

| 3 | Measuring process is slow. | It is a quicker process. |

| 4 | It is used for job specific work. | It is used for mass production of components in factories. |

| 5 | Instruments have graduation marks and specified least count. | Gauges have no graduation marks or least count. |

| 6 | An instrument is suitable for versatile applications of measurement. | A gauge is suitable for only one type of specific work. |